Comprehensive Sheet Metal Fabrication Services

Ace Prototype offers a custom sheet metal prototyping service to produce your parts in small series (from 1 to 250+ parts). Our capabilities allow us to produce your functional sheet metal parts in as little as 3 working days. We are able to produce partial or complete assemblies with mechanized welding. The principle of sheet metal is to work a sheet of metal using various stages and processes (cutting, folding, etc.) to give it the desired shape. The metal parts obtained can have different thicknesses, large sizes, and complex geometries. Commonly used materials for sheet metal work include aluminum, steel, stainless steel, brass, and copper.

To produce your fine sheet metal parts, we have a complete range of equipment: stamping presses, CNC press brakes, laser cutting machines, wire cutting machines, etc.

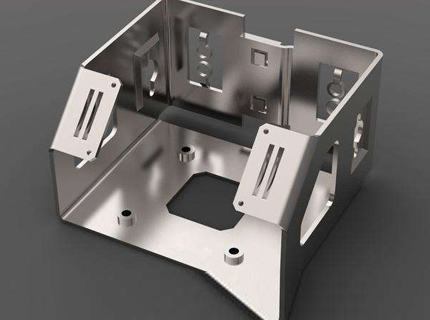

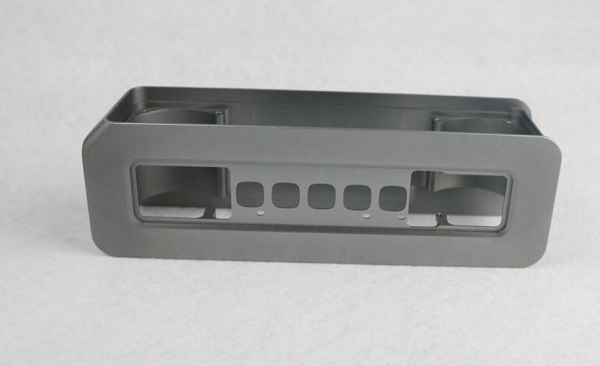

Example of sheet metal prototype parts:

Rapid sheet metal: process

The main processes of sheet metal processing include cutting, laser cutting, CNC bending, punching and shearing, stamping, rounding, riveting, welding and other methods. It can also be said to be the working principle and operation method of various equipment. All sheet metal processing processes are based on the need for sheet metal engineers to carefully design and label product drawings before operation. The main process terms are: blanking, pressure riveting, bending, shearing, blanking, punching, rising, pulling, riveting, ribping, corner-cutting, forming, punching and convex packing, punching tearing, printing, reaming, punching mesh, chamfering, teeth return, hole extraction, tapping teeth, leveling, drilling, counterbore, flat shooting, welding, spraying, assembly, etc.